Supplier’s due diligence

We explain what is included in identifying, assessing, preventing, mitigating, and remedying adverse impacts. In the guidance for each process requirement, you will also find supporting documents and suggested verifications to demonstrate compliance with the clause.

What is due diligence?

In the OECD Due Diligence Guidance, the concept is defined as follows:

“Due diligence is the process enterprises should carry out to identify, prevent, mitigate and account for how they address actual and potential adverse impacts in their own operations, their supply chain and other business relationships.”

Within the scope of the contract clause on due diligence for sustainable supply chains, the concept includes identifying, assessing, preventing, mitigating, and remedying adverse impacts on people, the environment, and society in your own operations and in your supply chains.

This means that the contract clause contains both results requirements and process requirements: to ensure compliance with the commitments on human rights, workers’ rights, the environment and business ethics, you must have a due diligence process. Simply put, the code of conduct describes what needs to be achieved, while the due diligence process explains how it should be achieved.

Excerpt from the contract clause

To ensure compliance with the commitments in the Supplier Code of Conduct in section 1, Supplier shall have a due diligence process in accordance with sections 2.1 – 2.7. The process shall be documented and applied from [contract start/other time determined by the contracting organisation]. Through this process, Supplier shall identify, prevent, mitigate and remedy adverse impacts on people, the environment and society in its own operations and supply chains. This means that:

Our due diligence process

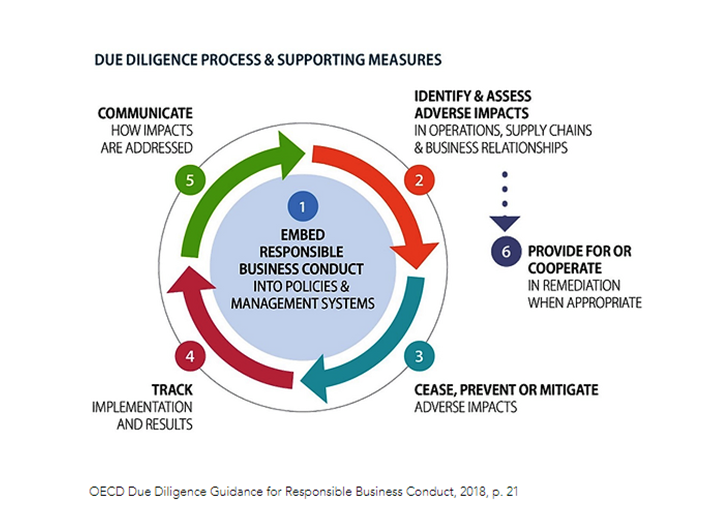

We have based our process requirements on the UN Guiding Principles on Business and Human Rights and the OECD Due Diligence Guidance for Responsible Business Conduct. These frameworks require companies to identify, prevent, mitigate and account for actual and potential adverse impacts.

However, since special contract conditions must be connected to what is purchased, we have not included all of steps 4 and 5 in the OECD wheel above. You are instead required to monitor the subject matter of procurement (section 2.5) and to participate in and cooperate with the contracting organisation’s monitoring of the commitments and the due diligence process (section 4.1).

Purpose of due diligence

The purpose of due diligence is for you to avoid causing or contributing to actual and potential adverse impacts and to try to prevent and mitigate adverse impacts linked to your operations, products or services through your supply chains.

- An actual adverse impact is an impact that has occurred or is occurring. Actual adverse impacts shall be subject to remediation.

- A potential adverse impact is an impact that may occur but has not yet done so. Potential adverse impacts are the same as risks of adverse impact. Potential adverse impacts shall be prevented or mitigated.

Under the process requirements, we will explain all concepts. We have also compiled them on a dedicated page.

Integral part of decision-making and risk management

Due diligence encompasses several related processes within your own operations and supply chains, such as health and safety management, supply chain risk assessments and supplier assessments. The due diligence process should therefore be an integral part of decision-making and risk management. It can also build on traditional risk management.

However, for many companies “risk” primarily refers to risk to the company – financial risk, market risk, operational risk or reputational risk. The due diligence process focuses on adverse impacts on people, the environment and society. If integrated into traditional risk management, it must therefore encompass risks to rights-holders, and not stop short at managing risks to the company.

Extent of due diligence

The extent of due diligence may be influenced by factors such as your company’s size, operating context, business model, position in the supply chain, and type of goods or services.

If you are a large company with many products, you may need more formalised and comprehensive processes than if you are a smaller company with a limited product range and shorter communication paths. But even small companies can have high risk profiles, such as suppliers of healthcare consumables or suppliers of food.

How can you manage limited resources?

Limited resources are a challenge for all suppliers, but SMEs in particular often have fewer staff and financial resources for due diligence. You may then choose to use collaborative methods and multi-stakeholder initiatives such as amfori BSCI.

SMEs can also take greater advantage of existing resources, such as publicly available information on risks in supply chains, and seek support from industry associations.

Feel free to use the Swedish National Agency for Public Procurement’s risk analysis service or the Swedish Regions’ own risk analyses, which you can find on the page Prioritised purchasing categories.

No shifting of responsibility

Each company in a supply chain has a responsibility to identify, prevent, mitigate and remedy adverse impacts. The contract clause is not intended to shift responsibility from sub-suppliers to suppliers.

However, if you are linked to adverse impacts, you are expected to use your leverage to prevent and mitigate adverse impacts that your sub-suppliers cause or contribute to.

Overcoming a lack of leverage

You may face practical and legal limitations on how much you can leverage subcontractors to prevent or mitigate adverse impacts. In particular, small and medium-sized enterprises may not have the necessary market power.

You can try to overcome this lack of leverage by collaborating in industry associations, or by participating in cross-industry or multi-stakeholder initiatives.

Documentation

It is relatively easy for a supplier to say that you respect people, the environment and society, but in order to fulfill the contract clause, you as a supplier must both know and show this.

Showing means communicating with affected individuals or groups, including public buyers, and providing a certain level of transparency and documentation that supports the statements. Documentation is a prerequisite for you to be able to show public buyers that you respect people, the environment and society. Examples of documentation include codes of conduct, supply chain mappings, risk assessments, audit reports, and action plans.

Under the process requirements you will find supporting documents and suggested verifications to show that you fulfill the contract clause.

Process requirements

Integrate commitments into policies and allocate responsibility for policies and due diligence

We explain the requirements for policies and how responsibilities shall be allocated between the board of directors, managers, and employees.

Identify and assess adverse impacts

We explain the concepts of risk suppliers, supply chain mapping, rights-holder consultations and particularly vulnerable groups, as well as how to prioritise risks based on likelihood and severity.

Prevent and mitigate adverse impacts that you cause or contribute to

We explain the responsibility to cease activities that cause or contribute to adverse impacts, establish action plans, and promote sustainable purchasing practices.

Prevent and mitigate adverse impacts linked to your operations

We explain the responsibility regarding supplier assessments, action plans, and the forwarding of requirements—including transparency—as well as the ability to temporarily suspend or terminate the contract.

Monitor the measures to prevent and mitigate adverse impacts

We explain what we mean by following-up action plans, meaningful consultations with rights-holders, and addressing deviations.

Enable complaints

We explain the key functions of complaints procedures, for which stakeholders they should be accessible, and the need to address submitted complaints.

Provide for remediation

We explain the concept of remediation, when remediation is required, the importance of engaging in meaningful consultation with affected rights-holders, and the need to assess whether they are satisfied with both the process and the outcome.

Guidance auditors

Contracting organisations monitor the supplier’s work through self-assessments and office audits. It is primarily during office audits that the auditor’s role becomes central.

At the bottom of each process requirement page, you will find a summary of the templates and tools relevant to that specific requirement. For ease of use, we have also gathered all templates and tools on this page. Please note that the templates for the due diligence policy, instruction, and action plan are only available here, as they are overarching and apply to all process requirements.

All templates and tools

- Due diligence policy template

- Due diligence instruction template

- Human rights policy template

- Environmental policy template

- Business ethics policy template

- Checklist for the board of directors

- Supplier code of conduct template

- Responsible sourcing instruction template

- Template for identification of risk suppliers (prioritised purchasing categories)

- Supply chain mapping template

- Supply chain risk assessment template incl. action plans and remediation plan

- Pre-qualification questionnaire

- Responsible Purchasing Code of Conduct (The Buyer Code)

- European Model Clauses (draft)

- Open Supply Hub

- Notification mechanism template

- Complaints procedure template

- Template for mapping procedures for remediation

- Remediation plan template for own operations

- Survey template for assessment of satisfaction with process and outcome

Guidance for suppliers on fulfilling the contract clause

Introduction to the contract clause

We explain what the contract clause is, why it exists, which international frameworks it is based on, and the extent of your responsibility.

Supplier’s commitments

We describe what is meant by human rights, workers’ rights, the environment, and business ethics.

Supplier’s due diligence

We explain what is included in identifying, assessing preventing, mitigating, and remedying adverse impacts.

Supplier’s reporting obligation

We clarify what you must do if you have reasonable grounds to assume that severe deviations are occurring or have occurred.