Process requirement 4

We explain the responsibility regarding supplier assessments, action plans, and the forwarding of requirements — including transparency — as well as the ability to temporarily suspend or terminate the contract.

Excerpt from the contract clause

Supplier shall use its leverage to prevent and mitigate actual and potential adverse impacts linked to Supplier’s operations, by

a) assessing risk suppliers based on the commitments in the Supplier Code of Conduct and the due diligence process, with a particular focus on the most significant risks identified,

b) establishing action plans for risk suppliers, with a particular focus on the most significant risks identified,

c) forwarding the commitments in the Supplier Code of Conduct (section 1) and the due diligence process (section 2) in writing to risk suppliers,

d) requiring risk suppliers to disclose their supply chains in accordance with the supply chain transparency requirement (section 4.4) and

e) ensuring the possibility of temporarily suspending deliveries from a sub-supplier while preventive and mitigating measures are implemented and, in the event of severe deviations that remain unaddressed, the possibility of terminating the contract with the sub-supplier concerned.

Using leverage

You shall use your leverage to prevent and mitigate actual and potential adverse impacts linked to your operations.

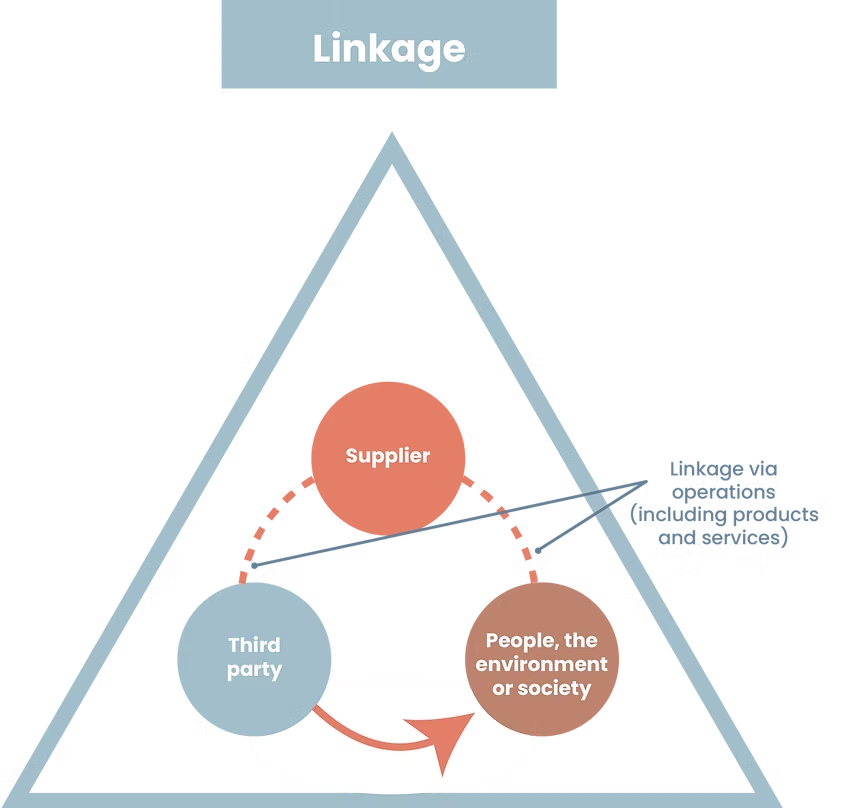

Linked to

You are linked to an adverse impact caused by a sub-supplier or another party, regardless of where in the supply chain it occurs. The linkage is defined by the relationship between your products, services, or operations and the adverse impact. Being linked to an impact is not the same as direct sourcing.

Examples of linkage

- You sell laptops from a brand whose manufacturer sources cobalt mined using child labour.

- You sell shirts with embroidered labels, where the manufacturer has outsourced the sewing process to child labourers who work from home.

- You sell bananas grown with pesticides that contaminate the surrounding community’s water supply and affect the fertility of workers.

If you are linked to an adverse impact, you are not directly responsible for it — the responsibility lies with the sub-supplier or party that causes or contributes to the adverse impact.

However, you have a responsibility to use your leverage to influence the party causing or contributing to the adverse impact to cease, prevent, or mitigate it.

Leverage is considered to exist where the supplier has the ability to effect change in the wrongful practices of the party causing the adverse impact.

The approach depends on the leverage you have over the sub-supplier or the party causing the harm, the impact itself, as well as industry and business relationships. Factors such as direct control, the importance of the business to the sub-supplier, and your market influence may also play a role.

Here are examples of how you can use your leverage:

- Forward commitments and the due diligence process throughout the supply chain.

- Require transparency from sub-suppliers regarding their supply chains.

- Choose certified products.

- Support sub-suppliers in developing and implementing action plans.

- Monitor sub-suppliers’ actions to prevent and mitigate adverse impacts.

- Engage in dialogue with sub-suppliers via letters, emails, calls, or meetings.

- Build sub-suppliers’ capacity through training, management system upgrades, grievance mechanisms, and protective equipment.

- Offer long-term contracts to sub-suppliers that improve their sustainability efforts.

- Facilitate financing through loans, direct support, or low-interest rates.

- Collaborate with other buyers through industry organisations and multi-stakeholder initiatives.

- Encourage sub-suppliers’ participation in industry organisations and multi-stakeholder initiatives.

- Collaborate with authorities to improve legislation, oversight, and enforcement measures.

If you lack leverage, you should consider ways to strengthen it, such as through long-term relationships, commercial incentives, dialogue with management, or collaboration with other stakeholders in multi-stakeholder initiatives.

In the contract clause, we have defined five ways to exercise leverage over risk and sub-suppliers.

Assessing risk suppliers

You shall assess risk suppliers based on the commitments in the Supplier Code of Conduct and the due diligence process, with a particular focus on the most significant risks identified.

The supplier assessment shall cover:

- The risk supplier’s capacity, willingness and implementation of due diligence

- The most significant risks identified

You shall assess new risk suppliers before entering a business relationship and existing risk suppliers that have not yet been assessed or when the context has likely changed.

There are several types of supplier assessments. Below, we outline the most common ones.

Self-assessments and pre-qualification

Many suppliers conduct supplier assessments through self-assessments, often as a pre-qualification of suppliers. For self-assessments and pre-qualifications to be valuable, you must request verification to ensure that the information provided is accurate.

To make it easier for you, we have developed a pre-qualification questionnaire that you can use to assess suppliers based on:

- due diligence for responsible sourcing

- traceability and transparency

- the most significant risks.

The pre-qualification questions for due diligence are available at three different levels:

- frontrunner

- advanced

- basic

The questionnaire will help you determine which level you should use depending on the supply chain risk, the size of the suppliers in the procurement, and the industry sustainability maturity.

In the questionnaire you will also find pre-qualification questions for the relevant European Sustainability Reporting Standards, but it is up to you to determine the most significant risks.

The questionnaire can be found further below under Templates process requirements 4. It is not a requirement to use our questionnaire to assess suppliers, it should be seen as support.

Tip! If you want to use pre-qualification questions as award criteria or contract clauses instead, ask your favorite AI to transform the questions. When we asked AI to transform the traceability and transparency questions into a contract clause, this is what we got:

Supply Chain Mapping

Supplier shall by [day, month, year] provide a complete mapping of the supply chain for [components/key materials] to Buyer, including all tiers of suppliers to the source of raw materials. Supplier shall maintain up-to-date records of all entities involved in the supply chain and disclose this information upon request.

Origin Verification

Supplier shall track and verify the origin of [components/key materials] to ensure they are not associated with forced labour, deforestation, or conflict. Supplier shall implement due diligence measures to confirm compliance with this requirement.

Supplier Disclosure Obligations

Supplier shall require all suppliers to disclose sourcing details and provide supporting documentation verifying the origin and traceability of [components/key materials]. Supplier shall ensure that these disclosures are accurate and accessible for review.

Chain-of-Custody Documentation

Supplier shall provide comprehensive chain-of-custody documentation for [components/key materials], demonstrating full traceability from raw material extraction to the final product. Supplier shall retain such records for at least [X] years and make them available for audit upon request.

Audits and Verification

Supplier shall conduct regular audits and third-party verifications of sub-suppliers to confirm the integrity of traceability claims for [components/key materials].

Addressing Traceability Gaps

In the event of traceability gaps or incomplete supply chain data, Supplier shall develop and implement a corrective action plan to improve supply chain transparency. Supplier shall report any gaps and the steps taken to resolve them to Buyer within [X] days of discovery.

Legal and Industry Compliance

Supplier shall ensure compliance with all applicable legal and industry traceability requirements, including but not limited to the [EU Deforestation Regulation, UFLPA, OECD Due Diligence Guidance], and any other relevant national or international standards.

Transparency and Disclosure

Upon request from [Buyer/Regulator], Supplier shall provide full transparency regarding supply chain traceability, including access to all relevant records, documentation, and data related to [components/key materials]. Supplier shall promptly respond to such requests within [X] days.

Breach and Remedies

Any failure to comply with the obligations under this clause shall constitute a material breach of the agreement. In the event of non-compliance, Buyer reserves the right to take appropriate remedial actions, including suspension of orders, contract termination, or other legal remedies as deemed necessary.

Site visits and inspections

If you have the capacity and leverage to conduct site visits or inspections, these should cover actual and potential adverse impacts on people, the environment and society, not just product quality or the supplier’s manufacturing capacity. Here are important aspects of site visits and inspections:

- Review of policies and documents, including recruitment guidelines, contracts, payroll, work schedules, time cards, and overtime compensation.

- Interviews with workers to identify risks.

- Inspection of premises, including accommodation, to assess health, safety and the environment.

- Consultation with local organisations and human rights defenders to understand the impact on communities at local, regional and national levels.

- Mapping of government contacts, such as permits, supervision and tax and customs payments.

Multi-stakeholder initiative supplier assessments

In some cases, credible supplier assessments may already exist through multi-stakeholder initiatives such as Ecovadis and amfori BSCI. If you are a member of such initiatives, you should review the results, prioritise actions to prevent and mitigate adverse impacts, and follow-up improvements.

You should also encourage regular reviews of the initiatives, particularly their effectiveness in identifying, assessing, preventing and mitigating adverse impacts.

Third-party reports and assessments

If you lack the capacity or leverage to conduct your own site visits or inspections, you can request factory audit reports, occupational health and safety inspection reports, and impact assessments conducted by third parties, such as other buyers, as part of your supplier assessments. It is often in the interest of risk suppliers to share this information to avoid repeat inspections. However, always review the methodology and objectivity of the inspectors to ensure the credibility of the reports.

Particular focus on the most significant risks

As with all due diligence, focus shall be on the most significant risks, assessed based on their likelihood and severity. This means that supplier assessments shall reflect your risk prioritisation.

For support on how to prioritise risks based on likelihood and severity, see Process requirement 2.

Suggested verifications

- Instructions describing how you assess risk suppliers based on the most significant risks identified and the risk supplier’s capacity, willingness and implementation of due diligence.

- Self-assessments or pre-qualifications, for sample products.

- Reports from site visits or inspections, for sample products.

- Reports from multi-stakeholder initiatives, for sample products.

- Third-party reports, for sample products.

Guidance for auditor

Fulfils requirement

The company has instructions or equivalent documentation/templates that describe how it assesses risk suppliers based on the commitments and the due diligence process, including:

- How supplier assessments cover the risk supplier’s capacity, willingness and implementation of due diligence.

- How supplier assessments target the most significant risks identified, which assumes that there is a risk assessment.

- How supplier assessments are conducted before a business relationship begins, for existing risk suppliers that have not yet been assessed, and when the context is likely to have changed.

- How supplier assessments are carried out — through self-assessments, pre-qualifications, site visits, inspections or by obtaining audit reports from third parties (including multi-stakeholder initiatives).

Supplier assessments are available for sample products and these cover both the supplier’s due diligence and the most significant risks identified.

Does not fulfil requirement

The company lacks instructions or equivalent documentation/templates that describe how it assesses risk suppliers based on the commitments and the diligence process, or they are incomplete:

- Supplier assessments do not cover the risk supplier’s capacity, willingness and implementation of due diligence.

- Supplier assessments do not focus on the most significant risks identified, for example because there is no risk assessment.

- It is not clear that supplier assessments are carried out before business relationships begin, for existing risk suppliers that have not yet been assessed and when the context is likely to have changed.

- It is not clear how supplier assessments are carried out — through self-assessments, pre-qualifications, site visits, inspections or by obtaining audit reports from third parties (including multi-stakeholder initiatives).

Supplier assessments for sample products are missing or incomplete. Examples of shortcomings may include that they only cover the supplier’s due diligence or the most significant risks identified.

Establishing action plans

You shall establish action plans for risk suppliers, with a particular focus on the most significant risks identified.

This requirement is not about the action plans risk suppliers establish during audits. It concerns your own action plans, which shall outline your measures and expectations on risk suppliers. Depending on your leverage and relationship, these plans can be developed in consultation with risk suppliers.

The action plans shall be documented, communicated with risk suppliers if developed in consultation, and include:

- Measures – descriptions of how you intend to prevent and mitigate the adverse impact, including the identified root cause.

- Timeframes – dates for when the measures must have been implemented.

- Responsible persons – persons responsible for the implementation of the measures.

In the supply chain risk assessment template we have developed, available under Templates process Requirement 4, we help you create action plans to address adverse impacts in the supply chain.

Below are proposed measures for the examples provided above.

| Examples of linkage | Proposed measures |

|---|---|

| You sell laptops from a brand whose manufacturer purchases cobalt that is mined using child labour. | Influence the brand to join the Responsible Minerals Initiative and steer their manufacturers towards sourcing cobalt from approved smelters and refiners. Consider ending the relation if they are not willing to improve their practices. |

| You sell shirts with embroidered labels, where the manufacturer has outsourced the sewing process to child labourers who work from home. | Emphasize that child labour must not occur and follow up to ensure that the manufacturer takes steps to facilitate the transition away from child labour. End the collaboration if the manufacturer is not willing to improve its work. |

| You sell bananas grown with pesticides that contaminate the surrounding community’s water supply and affect the fertility of workers. | Choose organic and fair trade bananas to encourage suppliers to become certified producers, together with other buyers. Ensure that the chosen certification covers both environmental and social aspects. |

Particular focus on the most significant risks

As with all due diligence, focus shall be on the most significant risks, assessed based on their likelihood and severity. This means that action plans shall reflect your risk prioritisation.

In the child labour example above, there are likely other risks in the factory, such as excessive overtime. Since child labour is likely the most significant risk, it should be addressed first.

Exact time frames must be determined individually. Once the most significant risks have been addressed, focus shall shift to the next most significant risks and thereafter in order of priority.

For support on how to prioritise risks based on likelihood and severity, see Process requirement 2.

What about certified products?

Purchasing certified products can be an effective risk mitigation measure, but does not replace the need to assess risk suppliers, establish action plans, forward the commitments and the due diligence process, and require transparency in the supply chain.

Certified products are often supported by multi-stakeholder initiatives that work with suppliers to develop action plans and provide technical guidance. The decision to purchase certified products should be documented in your action plan as the selected risk mitigation measure.

Suggested verifications

- Instructions describing how you establish action plans for risk suppliers, with a particular focus on the most significant risks identified.

- Action plans for suppliers of sample products.

Guidance for auditor

Fulfils requirement

The company has instructions or equivalent documentation/templates that describe how it establishes action plans for risk suppliers/prioritised purchasing categories, including:

- How the action plans take aim at the company’s own actions (e.g. decision to buy certified products) but that this includes expectations on risk suppliers.

- How the action plans focus on the most significant risks (assessed based on likelihood and severity).

- How the action plans include measures, timeframes, and responsible persons.

There are action plans for sample products and these take aim at the company’s own actions, focus on the most significant risks and include measures, timeframes and responsible persons.

Does not fulfil requirement

The company lacks instructions or equivalent documentation/templates that describe how it establishes action plans for risk suppliers/prioritised purchasing categories, or they are incomplete:

- It is not clear that the action plans take aim at the company’s own actions (e.g. decisions to buy certified products) including expectations on risk suppliers.

- It is not clear that the action plans focus on the most significant risks (assessed based on likelihood and severity).

- The action plans lack measures, timeframes or responsible persons.

Action plans for sample products are missing or incomplete. Examples of shortcomings may be that they do not target the company’s own actions, do not focus on the most significant risks and/or do not include measures, timeframes and/or responsible persons.

Forwarding requirements

You shall forward the commitments in the Supplier Code of Conduct and the due diligence process in writing to risk suppliers.

The most common ways to forward commitments and due diligence are through contracts and codes of conduct. There is no requirement to use the Swedish Regions’ Supplier Code of Conduct or the exact contractual clause on due diligence for sustainable supply chains.

However, you should ensure, as far as possible, that the commitments in the Supplier Code of Conduct are covered. This often requires a comparison between the regions’ code of conduct, your code of conduct, and the policies of the risk suppliers. But since it is not always feasible to ensure full alignment, we have outlined below how to approach multi-stakeholder initiatives’ codes of conduct, brands that do not sign codes of conduct, and sustainability declarations. Another way of solving the problem with different content in yours and risk suppliers policies is to refer to both in agreements.

For the due diligence process, it is sufficient to communicate that the risk supplier shall work in accordance with the UN Guiding Principles on Business and Human Rights and the OECD Due Diligence Guidance for Responsible Business Conduct. This meets our requirements.

Should you opt to use the European Model Clauses (currently in draft form), these incorporate sufficient provisions on due diligence including forwarding of the due diligence process.

Multi-stakeholder initiatives' codes of conduct

Sub-suppliers often have many customers and may supply products and services to multiple industries, so it can be impractical and burdensome to unilaterally impose your own requirements without considering existing or potentially conflicting expectations from other customers.

To address this challenge, you can follow international or industry-specific standards. However, it is important to compare these standards with the commitments. If there are discrepancies, you should work within the initiative to revise the standards to align with the requirements.

Brands that do not sign codes of conduct

Some sub-suppliers, especially multinational brands in the footwear and electronics industries, for example, often refuse to sign the codes of conduct of smaller retailers.

Also in these cases, you should review the brand’s policies in relation to your commitments. If there are discrepancies, you may want to consider joining multi-stakeholder initiatives to strengthen your leverage.

Regions' use of sustainability declarations

Regions can support you in the forwarding by using sustainability declarations in the tender process.

These declarations focus on the brand owners’ commitments and due diligence processes, rather than your own. Sustainability declarations are particularly useful in industries where retailers have limited leverage over brands, such as electronics and automotive.

You are responsible for forwarding the sustainability declaration to the brand owners during the tender process, to ensure their commitment. The brand owners sign the declaration, which is then submitted by you as part of the tender. One advantage of this is that the brand owners are aware that their products are included in public procurement and the requirements that are set.

This does not replace your responsibility. You are still responsible for the contract clause, and all communication with the brand owners goes through you. But together we can strengthen our leverage.

Suggested verifications

- Instructions for forwarding the commitments and the due diligence process.

- Contractual agreements that include the commitments and the due diligence process, for sample products.

- Signed codes of conduct, for sample products.

- If you use a multi-stakeholder initiative’s code of conduct, you shall provide a comparison against the commitments and a description of how you work to revise the code within the initiative, if necessary.

- If you sell goods from a brand that does not sign your code of conduct, you must provide a comparison of their code against the commitments and a description of any actions taken to increase your influence.

- Signed sustainability declarations, for sample products.

Guidance for auditor

Fulfils requirement

The company has instructions or equivalent documentation/templates that describe how it forwards the commitments and due diligence process in writing to risk suppliers, including:

- How this is done through agreements and codes of conduct (see examples in the guidance).

- How the risk supplier is required to, in turn, forward the commitments and due diligence process.

There is evidence to show that the commitments and due diligence process have been forwarded for sample products.

- If a multi-stakeholder initiative’s Code of Conduct is used, the company has compared the Code with the commitments and can explain how it is working to influence the initiative to revise the Code, if necessary.

- If the company sells products from a brand that does not sign the company’s code of conduct, the company has compared the brand’s code of conduct with the commitments (and its own code).

- If the contracting organisation uses sustainability certificates, these are signed by the brands.

Does not fulfil requirement

The company lacks instructions or equivalent documentation/templates that describe how it forwards the commitments and due diligence process in writing to risk providers, or they are incomplete:

- It is not clear that the commitments and/or due diligence process are forwarded through agreements or codes of conduct.

- There is no requirement for the risk supplier to, in turn, forward the commitments and due diligence process.

There is no evidence to show that the commitments and due diligence process have been forwarded for sample products, or it is incomplete:

- The commitments have been forwarded but not the due diligence process.

- The company uses a multi-stakeholder initiative’s Code of Conduct without having compared the Code with the commitments and/or without being able to explain how it works to influence the initiative to revise the Code, if necessary.

- The company sells products from a brand that does not sign the company’s code of conduct, without having compared the brand’s code of conduct with the commitments (and its own code).

- Signed sustainability certificates are missing.

Policies that have been updated after audit have not been forwarded to risk suppliers.

Requiring disclosure of supply chains

You shall require risk suppliers to disclose their supply chains in accordance with the supply chain transparency requirement.

This requirement will be adapted by the regions in each procurement, depending on the complexity, risks, and maturity of the industry, with final manufacturing facilities as a minimum.

Supplementing and finalising the contract clause

Requiring risk suppliers to disclose their supply chains leads to better supply chain mappings, improved risk assessments, and more effective preventive and mitigating measures.

Suggested verifications

- Contractual clauses for sample products, requiring risk suppliers to disclose their supply chains in accordance with the transparency requirement in the specific contract.

Guidance for auditor

Fulfils requirement

The company has instructions or equivalent documentation/templates that describe how it sets requirements for transparency in the supply chain.

The agreements with suppliers of sample products contain conditions – either in the original agreement or as an addendum – that oblige them to disclose their supply chains at least in accordance with the contracting organisation’s transparency requirements.

Does not fulfil requirement

The company lacks instructions or equivalent documentation/templates that describe how it sets requirements for transparency in the supply chain.

The agreements with suppliers of sample products do not contain any conditions – either in the original agreement or as an addendum – that oblige them to disclose their supply chains at least in accordance with the contracting organisation’s transparency requirements.

Suspending or terminating contract

You shall ensure the possibility of temporarily suspending deliveries from a sub-supplier while preventive and mitigating measures are implemented and, in the event of severe deviations that remain unaddressed, the possibility of terminating the contract with the sub-supplier concerned.

There are several ways to address adverse impacts within a business relationship:

- Continue the business relationship while implementing risk-mitigating measures.

- Temporarily suspend the business relationship (suspend deliveries) while mitigation efforts are ongoing.

- Exit the business relationship (terminate the contract) if mitigation fails, is not feasible, or if the impact is severe.

The decision should be based on factors such as your leverage, how crucial the sub-supplier is to your operations, the severity of the adverse impact, and whether an exit itself could result in adverse impact.

Crucial sub-supplier

A sub-supplier is crucial if it provides a good or service that is essential to your operations and you have no reasonable alternatives. An example is if you are dependent on a rare earth element for your main product, for which sub-suppliers are only located in high-risk areas.

What to do if you continue the business relationship?

As long as the adverse impact persists and you choose to continue the business relationship, you should be able to account for your risk mitigation efforts. You must also be prepared to deal with any reputational, financial or legal consequences of the collaboration.

Recommended actions:

- Report internally and continue to monitor the situation.

- Reconsider the decision to continue the business relationship in the event of changed circumstances or as part of your long-term strategy to manage adverse impacts.

It may also be beneficial to explain your decision to continue the business relationship to the contracting region. Describe how the decision aligns with your policies and priorities, what steps you are taking to use your leverage, and how you will continue to monitor the situation.

Exit as a last resort

You should only consider exiting the business relationship as a last resort if:

- all attempts to prevent and mitigate the adverse impact have failed,

- the adverse impact is irreversible,

- there is a lack of realistic opportunities for improvement, or

- a severe adverse impact has been identified and the responsible party does not take immediate action to prevent or mitigate it.

Adverse impact of the decision

If you decide to terminate the business relationship, you shall identify and assess the adverse impact of the decision. This follows from Process requirement 2, which states that you shall identify and assess the adverse impact before major decisions or changes to the operations are implemented.

Responsible exit

If exit is deemed the most appropriate action, you should take the following steps for a responsible exit:

- Comply with national laws, international labour standards and collective agreements.

- Communicate escalation actions in advance to the sub-supplier.

- Inform the sub-supplier’s management and union about the decision, with a clear justification.

- Give the sub-supplier reasonable notice of termination, if possible.

Should you opt to use the European Model Clauses (currently in draft form), these incorporate sufficient provisions on suspensions and terminations of contract, as well as provisions on exiting as a last resort, assessments of adverse impacts of the decision, and responsible exits.

Suggested verifications

- Instructions describing how you ensure the possibility of temporarily suspending deliveries from a sub-supplier while preventive and mitigating measures are implemented and, in the event of severe deviations that remain unaddressed, the possibility of terminating the contract with the sub-supplier concerned.

- Contractual agreements for sample products, which allow for the temporary suspension of deliveries while preventive and mitigating measures are implemented, and termination of the contract in case of severe deviations.

Guidance for auditor

Fulfils requirement

The company has instructions or equivalent documentation/templates that describe how it can suspend deliveries from a sub-supplier while preventive and mitigating measures are implemented, as well as terminate the contract with the affected sub-supplier if severe deviations are not addressed.

The agreements with the suppliers of sample products contain conditions that enable the company to temporarily suspend deliveries while preventive and mitigating measures are implemented, as well as terminate contracts if severe deviations are not addressed.

Does not fulfil requirement

The company lacks instructions or equivalent documentation/templates that describe how it can suspend deliveries from a sub-supplier while preventive and mitigation measures are implemented, and/or terminate the contract with the relevant sub-supplier if severe deviations are not addressed.

The agreements with the suppliers of sample products lack conditions that allow the company to temporarily suspend deliveries while preventive and mitigating measures are implemented, and/or terminate contracts if severe deviations are not addressed.

Process requirements

Integrate commitments into policies and allocate responsibility for policies and due diligence

We explain the requirements for policies and how responsibilities shall be allocated between the board of directors, managers, and employees.

Identify and assess adverse impacts

We explain the concepts of risk suppliers, supply chain mapping, rights-holder consultations and particularly vulnerable groups, as well as how to prioritise risks based on likelihood and severity.

Prevent and mitigate adverse impacts that you cause or contribute to

We explain the responsibility to cease activities that cause or contribute to adverse impacts, establish action plans, and promote sustainable purchasing practices.

Prevent and mitigate adverse impacts linked to your operations

We explain the responsibility regarding supplier assessments, action plans, and the forwarding of requirements—including transparency—as well as the ability to temporarily suspend or terminate the contract.

Monitor the measures to prevent and mitigate adverse impacts

We explain what we mean by following-up action plans, meaningful consultations with rights-holders, and addressing deviations.

Enable complaints

We explain the key functions of complaints procedures, for which stakeholders they should be accessible, and the need to address submitted complaints.

Provide for remediation

We explain the concept of remediation, when remediation is required, the importance of engaging in meaningful consultation with affected rights-holders, and the need to assess whether they are satisfied with both the process and the outcome.